Honeywell’s DR Graphic paperless electronic data recorder represents the latest in recording technology with improved data resolution and reliability. Users benefit from:

-

quick visualization and documentation of the integrity of the process

-

faster data analysis

-

better access to secure data

-

reduced maintenance costs

Crystal Clear Display

XGA Resolution (1024 x 768 pixels)

Clear and intuitive operation

Industrial rugged Touch Screen with rapid navigation

Custom Screens

Comprehensive Connectivity

FTP, TCP/IP and RS485 Modbus Protocol

Modbus Master and Slave (option)

USB ports for keyboard and mouse

Data Storage

Removable Secure Digital (SD) card and USB storage

No moving parts - all solid state Flash memory

Security Stringent - Total Data integrity

ESS - Extended Security System

Password Network Synchronisation

Plus..

Remote Access - Advanced Software Data Analysis at

your PC and Remote Viewing

Independent Chart and Logging speeds

Global Language Support

Rapid review and replay of data at recorder

Approvals - CE, cCSAus, cULus, NEMA Type 4X /

IP66 option

Up to 50Hz (20 msec) Logging

Up to 16 Analogue Inputs

Reports - System generated

Concurrent Batch mode

AMS2750 Process Capabilities

New AMS2750 Pyrometry for Heat Treat applications

The X Series recorders are equipped with functionality you need to help your heat treat process comply with the requirements of AMS2750E

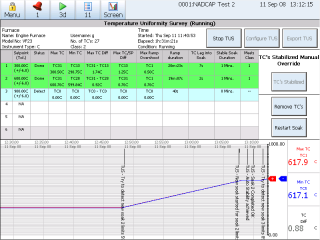

Temperature Uniformity Survey ( TUS) Mode

Add 10 credits to a standard Honeywell Multitrend SX and you have a ready to go survey recorder

A pre-configured survey screen provides a clear and concise summary of each survey temperatures, showing:

- The results at each set point soak, including

- Max TC number and value

- Min TC number and value

- TC Diff number and value

- Ramp duration

- Max Overshoot TC number and value

- TC lag into soak

- Duration of stable soak period

- The current set point status

- The current status and summary of the furnace.

- Up to 40 TC survey

Process Mode

In applications where multiple furnaces are using a single recorder the X Series solution has it covered.

Each recorder can independently automatically track the scheduling on up to 6 furnaces at the same time.

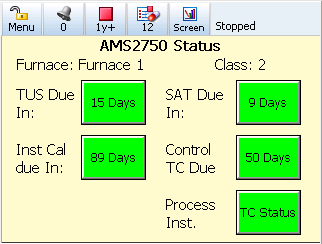

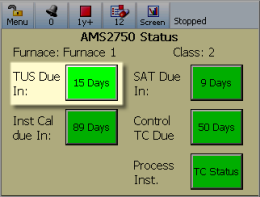

Each furnace has its own status screen clearly displaying the essential information to the operator.

Auto Thermocouple Tracking

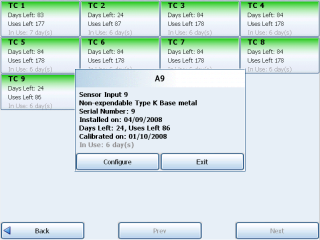

Whether Process or Survey recording, the X Series tracks TC usage:

- In line with section 3.1.8 of the AMS guide.

- Fully automated and ready to go

- Clear and intuitive summary of TC usage status

The TC use is summarised in a simple over view screen, and example is shown below. The tracking is

TC Usage

The usage of thermocouples must be tracked and is influenced by many factors:

Type, K, R, B etc

Expendable or Non-expendable

Time elapsed

Cycles completed

Temperature of cylce

The X Series tracking takes all these into account and simply reports to you what you need to know to ensure compliance with AMS2750.

Automated TUS, SAT and Calibration Tracking

The TUS, SAT and Calibration tracking by the X Series recorder helps you ensure that your heat treat process complies with the requirements of AMS2750

The details for each furnace tracked by the recorder is available on its own clearly labelled status page.

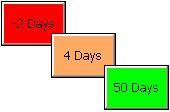

A traffic light system of Green, Amber and Red warns the operator of approaching deadlines.

Passwords & Security

Security is important and the AMS functions of the X Series recorders integrate fully and simply into the standard X Series password system, giving:

- Secure traceable operation

- Recorded audit trail

- Multi user

- Multi level

- Peace of mind

AMS2750 PC Report Tool

This Windows application converts the recorded data from the Temperature Survey into a .pdf report that complies with the requirements of AMS2705E.

This Windows application converts the recorded data from the Temperature Survey into a .pdf report that complies with the requirements of AMS2705E.

This simple to use intuitive tool is a breeze to use, you will be generating Survey reports within minutes of completing the survey.