The new Honeywell recorder represent the latest, best-in-class electronic data recording and display technology on the market. The recorders provide reliable, easy to use operation and offer greater security with more data storage capacity than other models. The TrendManager Pro Software makes data analysis a simpler, faster process for everyone involved, allowing the import of data from the recorder, analysis and exporting of data to other spreadsheet programs.

Crystal Clear Display:

• 5.7” High Resolution Digital Colour LCD (TFT)

• VGA Resolution (640 x 480 pixels)

• Clear and intuitive operation

• Industrial rugged Touch Screen with rapid navigation

• Custom Screens

Comprehensive Connectivity:

• 10/100 Ethernet (DHCP), Web, Email

• TCP/IP and RS485 Modbus Protocol

• USB ports for keyboard and mouse

Data Storage:

• On-board non-volatile memory - up to 4GB

• Removable Secure Digital(SD) and USB storage

• No moving parts - all solid state data storage

Security Stringent - Total Data integrity:

• Password Protection - 21CFR Part 11

• ESS - Extended Security System

Plus..

• Health Watch for preventative maintenance

• Remote Access - Advanced Software Data Analysis at your PC

• Independent Chart and Logging speeds

• Global Language Support

• Rapid review and replay of data at recorder

• Approvals - CE, CSA, UL, FM

• NEMA 4 / IP66 option

• Up to 50Hz (20 msec) Logging

• Up to 16 Analogue Inputs

• Remote Control Tool

• Reports - System Generated

• Concurrent Batch Mode

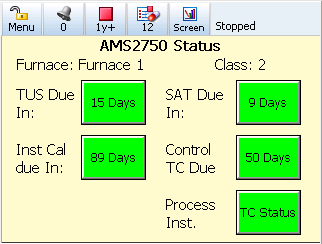

New AMS2750 Pyrometry for Heat Treat applications

The X Series recorders are equipped with functionality you need to help your heat treat process comply with the requirements of AMS2750

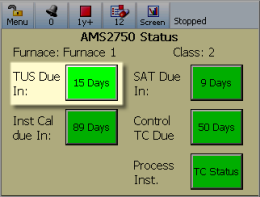

Process Mode

In applications where multiple furnaces are using a single recorder the X Series solution has it covered.

Each recorder can independently automatically track the scheduling on up to 6 furnaces at the same time.

Each furnace has its own status screen clearly displaying the essential information to the operator.

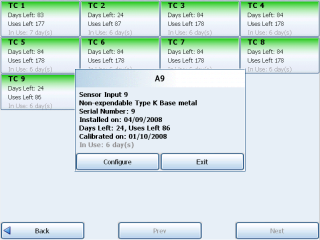

Auto Thermocouple Tracking

Whether Process or Survey recording, the X Series tracks TC usage:

- In line with section 3.1.8 of the AMS guide.

- Fully automated and ready to go

- Clear and intuitive summary of TC usage status

The TC use is summarised in a simple over view screen, and example is shown below. The tracking is

TC Usage

The usage of thermocouples must be tracked and is influenced by many factors:

Type, K, R, B etc

Expendable or Non-expendable

Time elapsed

Cycles completed

Temperature of cylce

The X Series tracking takes all these into account and simply reports to you what you need to know to ensure compliance with AMS2750.

Automated TUS, SAT and Calibration Tracking

The TUS, SAT and Calibration tracking by the X Series recorder helps you ensure that your heat treat process complies with the requirements of AMS2750

The details for each furnace tracked by the recorder is available on its own clearly labelled status page.

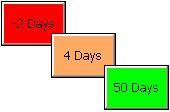

A traffic light system of Green, Amber and Red warns the operator of approaching deadlines.

Passwords & Security

Security is important and the AMS functions of the X Series recorders integrate fully and simply into the standard X Series password system, giving:

- Secure traceable operation

- Recorded audit trail

- Multi user

- Multi level

- Peace of mind